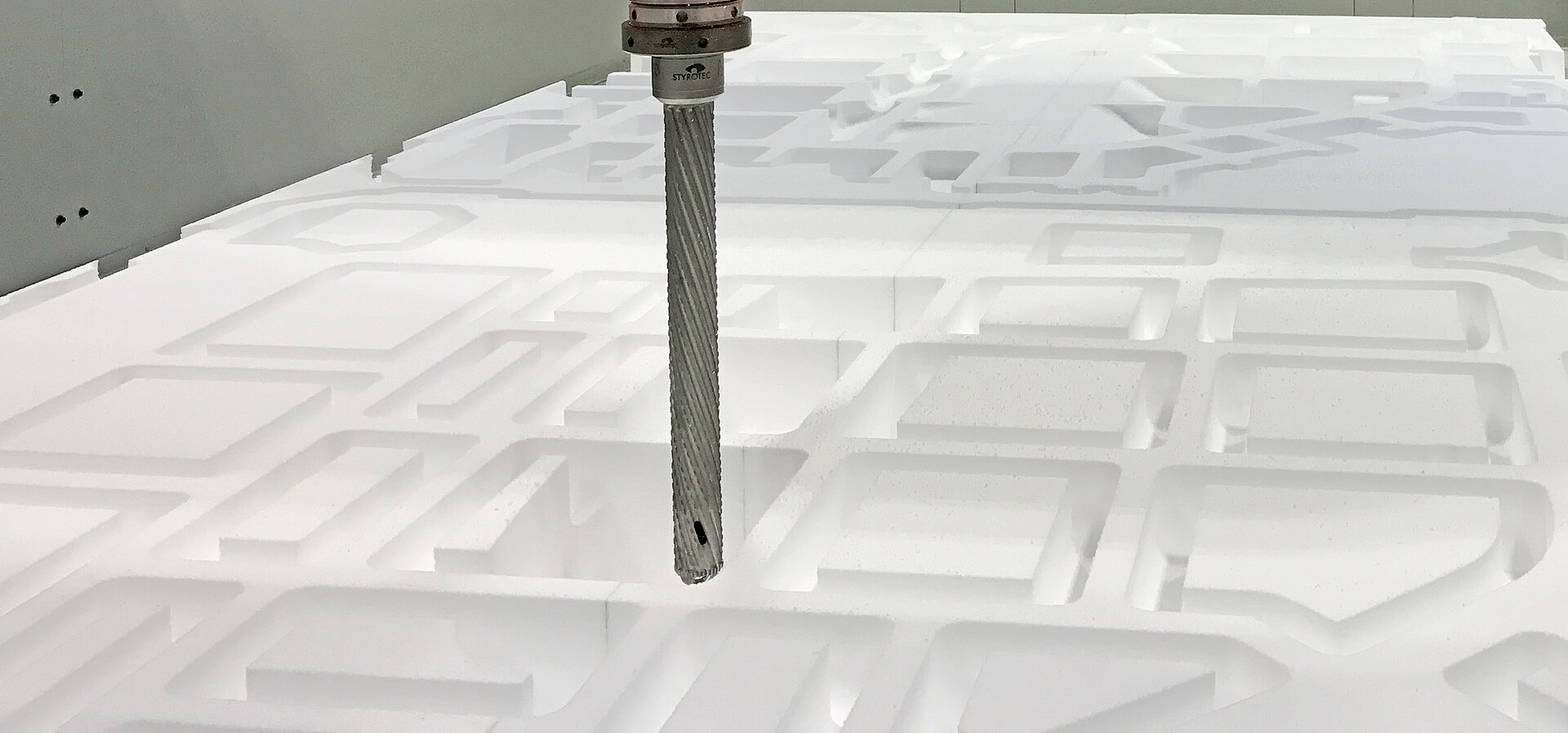

Hollow cutters made of hardened special steel for milling polystyrene, soft foam and hard foam as well as all similar materials. Particularly suitable for large-volume machining of polystyrene (EPS) and hard foam on CNC milling machines.

Together with special hollow milling spindles and high-pressure polystyrene exhausting units, the polystyrene chips can be sucked through the cutter and the hollow milling spindle. In order for this to work perfectly even when the tool is going inside of the block, we have perfectly dimensioned the suction openings and positioned them on the tool.

Due to the special cutting geometry combined with the chip breakers, very high feed rates can be achieved with low noise and super-surfaces. Even the thinnest ribs remain without breaking because of the low milling pressure. In the standard version we deliver these cutters, incl. a interchangeable tip of your choice, with the 78/8mm flange for clamping with M90x2 cap nut.

You will also find information about hollow milling cutters and other milling tools in our brochure.

There are a lots of possibilities to configure the right hollow milling tool for your application purpose.

The tip are interchangeable, which make it possible to exchange them fast after crashs or mechanical wear. This also safes money because you don't need to buy a complete new tool. The interchangeable tips are available in ball, flat, corner radius design or with an 45° chamfer.

For an extra charge, we deliver aour cutters on request with various direct shots. These are then balanced from the ground up and can therefore be used for speeds above 10,000 rpm.

The direct mount also offers better stability than the adapter and the tool length does not become unnecessarily larger.

The cutters also fit into more compact tool changers, making manual tool changes a thing of the past.

| hollow cutter | ||||||||

diameter (mm) / length (mm) | 15 | 25 | 30 | 35 | 40 | 45 | 50 | 60 | |

100 | ● | ● | ● | ● | ● | ● | ● | ● | |

150 | ● | ● | ● | ● | ● | ● | ● | ● | |

200 | ● | ● | ● | ● | ● | ● | ● | ● | |

250 |

| ● | ● | ● | ● | ● | ● | ● | |

300 |

| ● | ● | ● | ● | ● | ● | ● | |

350 |

|

| ● | ● | ● | ● | ● | ● | |

400 |

|

| ● | ● | ● | ● | ● | ● | |

450 |

|

|

|

| ● | ● | ● | ● | |

500 |

|

|

|

| ● | ● | ● | ● | |

550 |

|

|

|

|

|

|

| ○ | |

600 |

|

|

|

|

|

|

| ○ | |

● standard; ○ optional; - not available

------------------------------------------------------------------------------------------------------------------------

Are you interested in plane milling cutters? Click here for our plane milling cutters!

------------------------------------------------------------------------------------------------------------------------

All cutters are surface hardened and true running tested with a speed release up to 6,000 rpm, unless noted otherwise.

We additionally offer to balance all cutters with a balancing grade G2.5 for an extra charge.

The cutters from 500mm length must always be balanced. Even milling cutters with SK or HSK direct receptacle must always be balanced.

This gives you an absolute precision tool with perfect concentricity and a long service life.