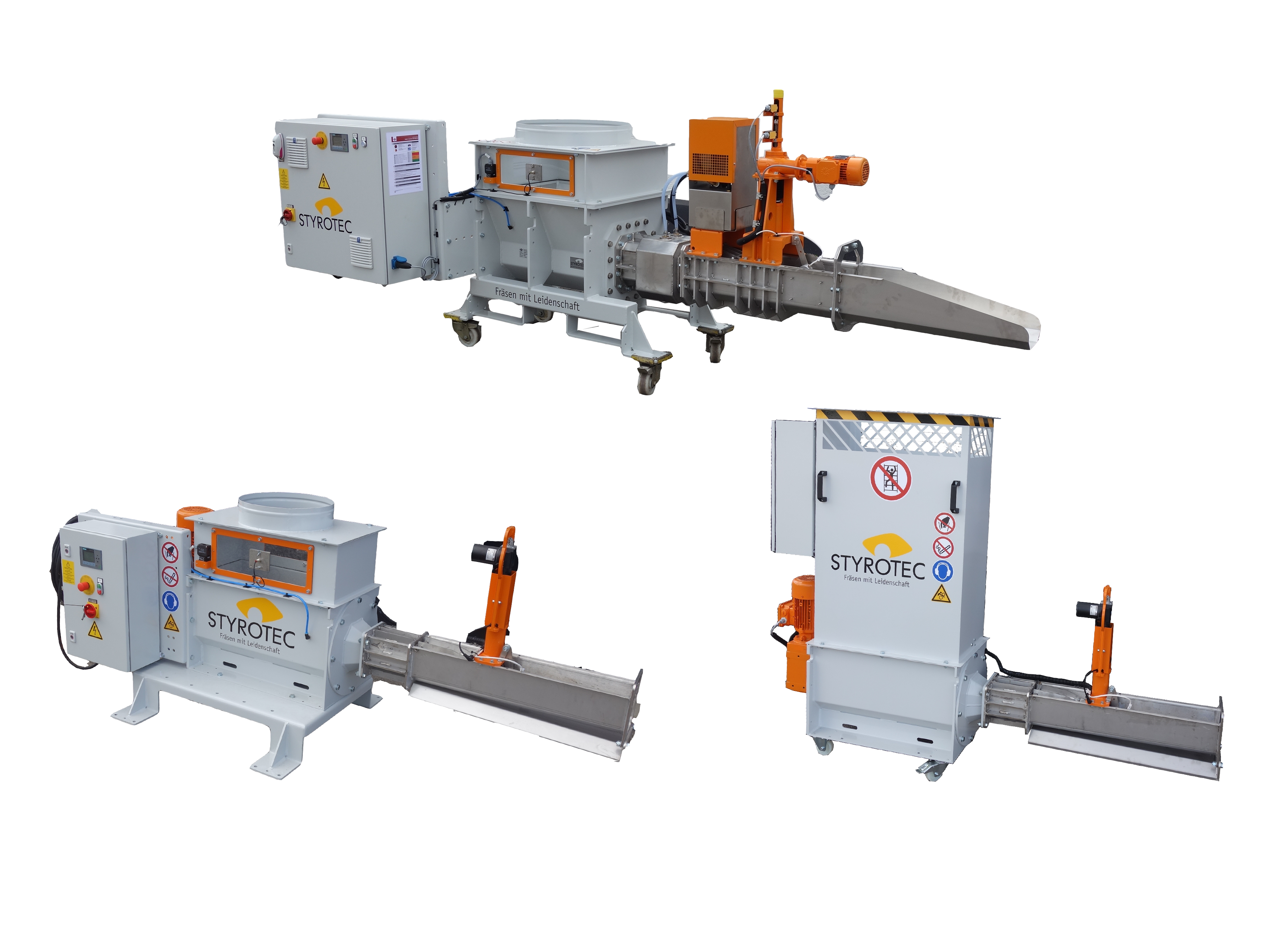

STYROBRIQ

Polysterene Press

With an innovative technology, the press compacts bulky foam waste from EPS (Styropor®) into easy-to-handle blocks in an extremely economical way.

The extreme volume reduction achieved in a ratio of up to 40: 1 not only saves a considerable amount of transport and disposal costs, but the blocks produced are also recyclable as raw materials and contribute to rapid amortization.

- Long service life thanks to robustly designed drive technology

- Efficient operation thanks to fully automatic pressure regulation, with predetermined breaking point function and individually programmable block length

- Hours of operation without overheating and merging with optional water-cooled pressure channel

- Convenient, fully automatic mode of operation thanks to state-of-the-art control

- High efficiency due to low operating and maintenance costs

- Easy commissioning through plug-in delivery